doi: 10.58763/rc202315

Scientific and Technological Research Article

History of production and its challenges in the current era

Historia de la producción y sus retos en la era actual

Nicolás Afanador Cubillos1 ![]() *

*

ABSTRACT

This qualitative and documentary research analyzes the significant advances that production and operations have had over time, seeking to establish the management approach's progress in each of the historical stages. It is possible to confirm that this has evolved from a perspective focused on manufacturing to a philosophy focused on a comprehensive view of the supply chain. This highlights the main obstacles to facing current challenges and, at the same time, points out the almost hegemonic short-term vision that has characterized production and operations management throughout the 20th century, as opposed to the demand current broader perspective.

Keywords: integral operations management, manufacturing management, operations and supply management, lean production, digital transformation

JEL classification: D24; O14.

RESUMEN

Esta investigación cualitativa y documental analiza los principales avances que ha tenido la producción y operaciones a lo largo del tiempo, buscando establecer el avance que ha tenido el enfoque gerencial en cada una de las etapas históricas, se logra establecer que este ha evolucionado desde una perspectiva centrada en la manufactura hasta una perspectiva centrada en una visión integral de la cadena de suministro. Esto pone en evidencia los principales obstáculos para hacer frente a los retos actuales y, al mismo tiempo, señala la casi hegemónica visión de corto plazo que ha caracterizado a la gerencia de producción y operaciones a lo largo del siglo XX, en contraposición a la exigencia actual de perspectiva más amplia.

Palabras clave: gerencia integral de las operaciones, gerencia manufacturera, gerencia de operación y suministros, producción esbelta, transformación digital

Clasificación JEL: D24; O14.

Received: 19-05-2022 Revised: 17-09-2022 Accepted: 15-12-2022 Published: 13-01-2023

Editor: Carlos

Alberto Gómez Cano ![]()

1Fundación Universidad de América. Bogotá, Colombia.

Cite as: Afanador, N. (2023). Historia de la producción y sus retos en la era actual. Región Científica, 2(1), 202315. https://doi.org/10.58763/rc202315

INTRODUCTION

The enterprise concept has been closely linked to the role of production processes within organizations. The role of production should not be seen only as an activity within the company but as the operating unit in a company that conceives and obtains the products (goods and services) based on the different transformation processes and meets, at the same time, customer expectations and business objectives based on competitive services, the development of continuous improvement strategies and quality. This involves 1) the design of production systems, 2) the design of capabilities, 3) the design of goods and services, 4) quality management, 5) process improvement, 6) job design, and 7) inventory management that generates value to increase both satisfaction and alternatives available to customers (Heizer et al., 2017).

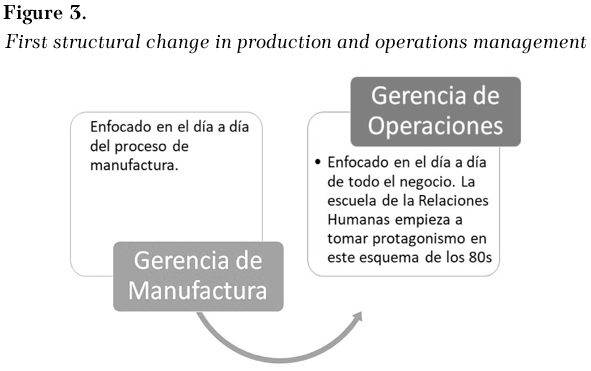

The rich and intricate relationship that production and operations have in organizations poses a set of challenges that we can classify into 1) challenges associated with market development (Aguilar-Barceló & Higuera-Cota, 2019; Rodríguez, 2017); 2) challenges associated with economic changes (Silva & Gómez, 2018); 3) challenges associated with productive factors; 4) challenges associated with the technological environment (Cárdenas et al., 2021); and (5) challenges associated with emerging business models (Barrientos-Felipa, 2017) as shown in figure 1.

Source: Own elaboration.

Note: the figure appears in its original language.

These challenges are the consequences of the design function, function control, long and short term in the organization that fulfills the production and operations area in a company, which are aligned to achieve improvement in the creation of economic value in the company and project towards a sustainable and competitive future (Buchanan & Gibb, 2007; Meredith & Pilkington, 2018).

An organization's design functions are all those responsible for configuring the operations system and providing an overall framework. Several functions are design-oriented, product development, quality management, facility location and layout, and capacity planning. Through design, an organization can address the market challenges associated with the customization of goods and services and all those situations in which the customer takes active action. In addition, this substantive function of the company helps to delimit all those aspects related to the adoption and proper use of technologies; therefore, it is in the design function where a larger set of challenges lies.

The functions of forecasting, production planning and control, supply chain management, and maintenance management are mainly tactical and are supported in a wide range of cases. This document will discuss the different components integrated into production and operations management using a historical tour to show when the operation and operations management migrates from a short-term vision to a different one.

METHODS

Empirical studies on production, operations, and digital transformation published between 2000 and 2021 were found through Sage Journal, ScienceDirect, and Elsevier. Query terms included production management, operations management, digital transformation, and lean production: a first criterion for selecting studies was their impact. Therefore, quartiles one and two were selected, as well as impact factors higher than 0.5; the second criterion was the core subject matter associated with management, supply chain, and value chain; and finally, some references made in these articles were used.

Using these criteria, 50 papers from empirical studies and books were selected for inclusion in this review. These studies were discussed by presenting the theoretical contributions and the evolution of management in operations and production.

RESULTS

Historical review of production and operations

The history of production and operations has evolved from the first steps taken by Taylor to Kim Clark under the schemes of the administration of productive factors, automation, adoption of current technologies, quality management, and maximization of the benefits of managerial management. Under this scheme, the evolution of production and operations throughout history will be discussed, together with the evolution of the managerial approach that has led to integrated operations management.

Historical nature, concepts and the prelude to handicraft production

The digital boom, which dates back to the seventies, was the starting point for Knowledge Management (Dalkir, 2011), which permeates the different functional areas of organizations and the production and operations areas. With the accelerated use of digital tools in companies, the use of Information and Communication Technologies (ICT) has given it a leading role in its incorporation into productive factors. Therefore, four productive factors are referred to: Capital, Land, Labor, and Technology.

The original use of Capital, Land, and Labor as fundamental elements in microeconomic theory comes in essence from the first evidence of the specialization of labor in the Egyptian culture more than 6000 years ago. The Egyptians ' construction of the pyramids evidenced their knowledge of planning, organization, and control. Later, within the Hebrew culture, around 1800 B.C., the use of workers, according to tasks, takes up the elements introduced in Egypt to leave the first evidence of the importance of the specialization of work in production and the availability of dispersed labor force. In summary, whether in the Far East, the Greek culture, or the two cultures above, work specialization, planning, and organization have been. They will continue to be fundamental pillars in operations management (Shaw, 2021).

Craftsmanship centered on "the master craftsman," whose learning was based on tacit knowledge transmitted from the master to the apprentice or journeyman, is the remote origin of the industrial enterprise, as well as the search for perfection in its execution. On the other hand, the birth of the service industry, whose learning, unlike craftsmanship, is rooted in explicit knowledge and low systematization, arises from activities such as law, writing, and medicine, in which tradition and rites sustain its validity. The birth of industrialization is based more on production than on servuction.

Several key elements in this conceptualization were identified in Britain in the early eighteenth century. Moore identifies five essential inventions in the textile industry that laid the foundations for the Industrial Revolution: James Kay's invention of the Flying Shuttle in 1733, which enabled faster weaving of cloth; James Hargreaves' Spinning Jenny in 1764, which enabled mass spinning and increased production; in 1769, Richard Arkwright's Water Frame which made stronger yarns and saved labor by using animal or water power instead of human power; in 1779, Samuel Crompton's Mule Spinner which spun better and faster, with less effort and higher quality yarns; and in 1785, Edmund Cartwright's power loom which consolidated the weaving industry.

Two renowned researchers are worth mentioning: Adam Smith's book (1776), The Wealth of Nations, which focused on the benefits of division of labor and standardization of parts, and Charles Babbage's book (1832), The Economics of Machinery and Manufacturers, which included studies of time, research and development management, economic analysis for location decisions and the benefits to production costs and worker task specialization. These studies enabled the Wilkinson brand to offer superior-quality handmade products and led to a quality revolution in manufacturing. The lessons of part standardization, interchangeability, and the implications for quality are still emphasized today in lean production approaches (Piercy, 2012).

In the early 20th century, Frederick Taylor's work on developing four scientific management principles to increase worker productivity enormously impacted the practice of Operations Management. Taylor gained popularity following the publication of his books, and his testimony before the U.S. Senate that had implications for production management. This prompted authors such as Reinfeld (1960) to describe Taylor as "the father of modern management" (Piercy, 2012).

For his part, Henry Ford, heir to Taylorism, combined labor specialization, the use of interchangeable parts, and the moving assembly line to form a modern mass production system. Although Ford's model was displaced in the 1920s by greater volume and variety by General Motors, for authors such as Chase and Aquilano (2008), Ford's initiative is considered the greatest innovation of the machine age and the greatest triumph of mass production over craft production (Bessant & Tidd, 2015). In 1913, a production of 100,000 cars per year, which, one year later, doubled and, in five years, amounted to one million, proves the statement made by Bessant

Ford's introduction of a moving assembly line is fundamental in separating early 20th-century mass production from 19th-century high-volume industrial production in Europe. Developments after Ford's presupposed improvements to the Taylor-based scientific management system or production, such as the work of Henry Gantt or Walter Stewart (Buffa & Sarin, 1987).

The work of operations researchers in solving problems with mathematical and computational approaches during World War II created the entire field of operations research. It contributed invaluable to scheduling, forecasting, and capacity management in production. The combination of operations research and the study of Japanese approaches to production led to the foundation of new methods for tracking production flow, particularly in the 1960s, Joseph Orlicky's work on Material Resource Planning (MRP), later refined by Oliver Wright and George Plossl with the development of MRP II as a system for managing capacity planning in mass production, offered a radical change in lead time and availability. Issues related to operations research and human factors in production may fall outside the traditional scope of Operations Management, forming distinct bodies of knowledge (Chase & Aquilano, 2008; Heizer et al., 2017); however, each plays a critical role and takes on a leading role.

The era of lean production

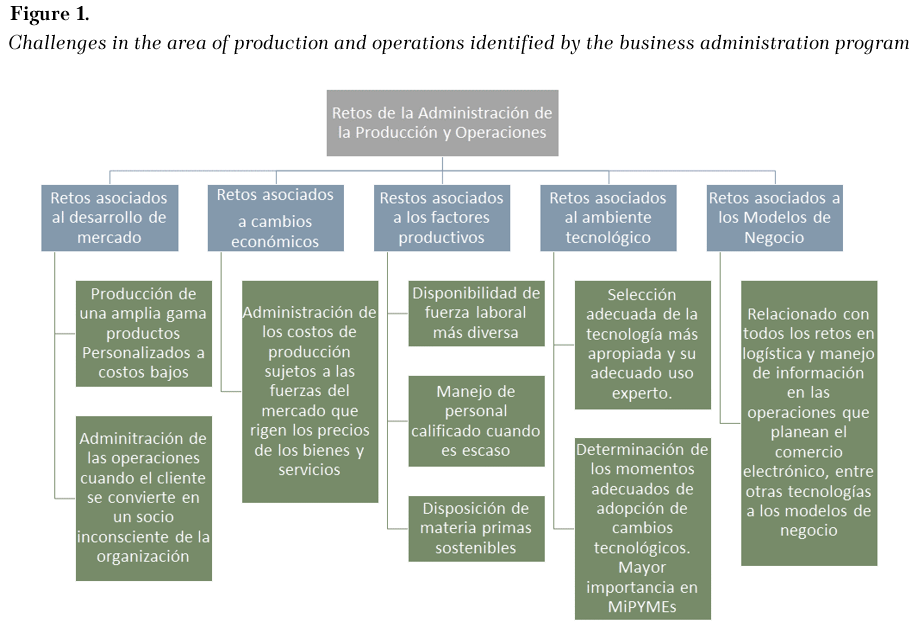

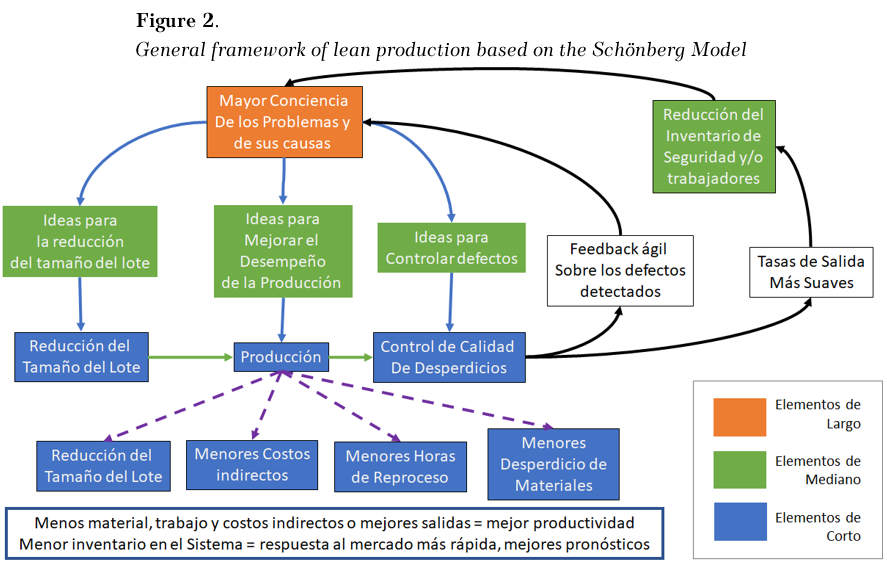

The most recent developments in operations management occurred in Japan with the studies of lean production systems, which redefined production management, task specialization, and worker control as done in previous decades. After World War II, Toyota's work designing a production system, different from mass production, laid the foundation for post-mass production operations management. The Japanese approach represents a paradigm shift in operations and organizational logic, providing higher quality at a lower cost than mass production by capitalizing on the knowledge gained due to the quest to reduce costs, inventories, rework, and waste (see Figure 2). These principles evolved the short-term vision that dominated the first half of the 20th century to give rise to the conscious recording of lessons learned. At this point, the competency in the technologist cycle focused on control (see Figure 3) is articulated around the technical cycle of the professional career of Business Administration, in which the use of quantitative tools to manage operations are pivots to nurture management and the construction of long-term strategies.

W. Edwards Deming, one of the key architects of the Japanese approach in the West, received a hostile reception in the United States for challenging scientific approaches to mass production and, subsequently, gained popularity with his new ideas on improving production quality (Piercy, 2012; Shingo & Robinson, 2017). Deming and Toyota's chief engineer, Taiichi Ohno, laid the groundwork for a new approach to operations management at Toyota: Japanese-style lean production. While not the first research on Japanese production, this was the most widely read and disseminated, with massive sales supporting mass post-production as a radical change (Fujimoto, 1999; Lepadatu & Janoski, 2020).

Throughout the movement, a broad demarcation between the Japanese approach to quality versus traditional mass production approaches is clear. The 1980s were based on attempts to compete with the Japanese with Western approaches developed in Japan. Other Western developments such as agility and mass customization have appeared, with little evidence, as alternatives to Japanese approaches; however, in the academic world, the rise of Japanese approaches and the subtlety with which Eastern and Western philosophies have been blended and the legitimacy of counter-approaches remain valid today.

Note: the figure appears in its original language.

Source: Own elaboration.

As seen in this brief historical overview, quality has taken leading roles in handicraft production and mass production through the contributions of Deming, who proposed the Westernized version of the continuous improvement scheme of the Eastern culture (Hillmer & Karney, 1997). Although, up to this point, the discussion of this document has been carried out around production and management, only up to the 1980s, a set of changes that have been developed around the discipline are shown in Figure 3 below.

Note: the figure appears in its original language.

Source: Own elaboration.

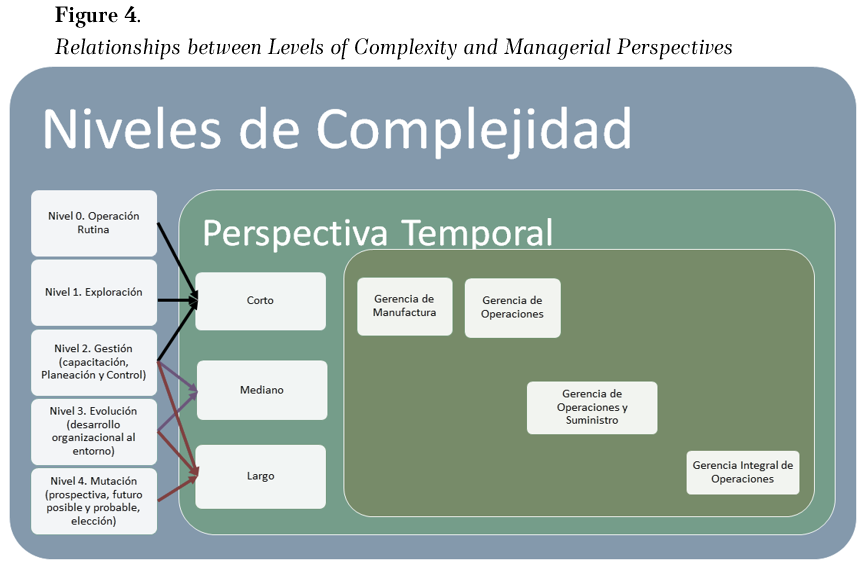

Table 1, presented below, is an extension of the main findings that have been presented in production and operations; likewise, it focuses on the managerial approach. The latter establishes a framework for chaining the levels of complexity addressed by both Larsen et al. (2013) and Valderrama and Tovar (2008).

|

Table 1. Historical evolution and main milestones of production and operations management |

|

||||

|

Management Approach |

Year |

Contribution |

Starring Involved |

|

|

|

Manufacturing Management |

1776 |

Labor specialization |

A. Smith |

|

|

|

1790 |

Interchangeable parts, cost accounting. |

E. Whitney |

|

||

|

1832 |

Division of labor by skill: allocation of jobs by skill, and fundamentals of time study. |

C. Babbage |

|

||

|

1900 |

Study of job movements (micro-movements). |

F. B. Gilbreth |

|

||

|

1901 |

Scheduling techniques for employees, machines, jobs in the manufacturing area. |

H. L. Gantt |

|

||

|

1911 |

Methods engineering and work measurement, division of labor, wage payment theory, human engineering. |

F. W. Taylor |

|

||

|

1913 |

Job specialization (automotive assembly line) |

H. Ford |

|

||

|

1915 |

Economic lot size in inventory control |

F. W. Harris |

|

||

|

1919 |

Tasks vs. time. Motion study and marriage of psychology and engineering. |

H. L. Gantt |

|

||

|

F. B. Gilbreth |

|

||||

|

1927 |

Human Relations and Hawthorne's study. |

E. Mayo |

|

||

|

1931 |

Statistical Process Control. Application of statistical inference in product quality, control charts. |

W. A. Shewhart |

|

||

|

1931 |

Efficiency of statistical quality control; 12 principles of efficiency and control charts. |

H. Emerson y W. A. Shewhart |

|

||

|

1934 |

Work sampling. Mathematical and computational techniques. |

L. H. C. Tippert |

|||

|

1935 |

Application of statistical sampling in quality control: sampling inspection plans. |

H. F. Dodge y H. G. Roming |

|||

|

1940 |

Application of operations research in World War II. |

P. Maynard y S. Blackett |

|||

|

1945 |

Fishbone diagram. Problem solving model in determining root causes of problems. |

K. Ishikawa |

|||

|

1947 |

Linear programming. |

G. B. Dantzig y W. Orchard-Hays |

|||

|

1950 |

Mathematical programming, nonlinear and stochastic processes. |

A. Charnes y W. W. Cooper |

|||

|

1950 |

Quality loss function, product and process design optimization, and quality engineering. |

G. Taguchi |

|||

|

1951 |

Total quality control (TQC). |

J. M. Juran |

|||

|

1954 |

Just-in-time |

T. Ohno |

|||

|

1960 |

Human engineering. Organizational climate (use of people's intellectual abilities). |

Abraham Maslow |

|||

|

Frederick Herzberg |

|||||

|

McLellan |

|||||

|

Elton Mayo |

|||||

|

1960 |

Organizational behavior (continuation of people in the work environment). |

L. Cummings y M. Porter |

|||

|

1960 |

Use of computers in companies and application of Materials Requirements Planning (MRP). |

Joseph Orlicky |

|||

|

1970 |

Mass production in service. MRP II |

Oliver Wigtht |

|||

|

Toyota Production System |

Shingo |

||||

|

1978 |

Manufacturing Strategy Paradigm, (the "five P's": People, Plants, Parts, Processes and Planning) variables of strategic and tactical decisions. |

Abernathy, Clark, Hayes y Weelwrigth |

|||

|

Operations Management |

1980 |

Deming Principles and Total Quality Management (TQM). JIT (Taichi Ohono) and TQC (J.M. Juran) are taken up again. |

W. Edward Deming |

||

|

1984 |

Theory of constraints |

Eliyahu M. Goldratt |

|||

|

Operations and supply chain management |

1990 |

Quality award, ISO 9000 certification |

ASQ; NIS; IOS |

||

|

Reengineering |

M. Hammer |

||||

|

ERP enterprise resource planning software |

Internet, Word Wide Web |

||||

|

Integrated Operations Management |

2000 |

Computer Integrated Manufacturing (CIM) |

William Abernathy |

||

|

Flexible Manufacturing Systems (FMS) and Factory of the Future. |

Kim Clark |

||||

|

Robert Hayes |

|||||

|

Steven Wheel |

|||||

|

Wrigth Wickhaml |

|||||

|

2010 |

Teamwork, coordination between designers, process and production engineers. |

||||

Source: Own elaboration based on Buffa and Sarin (1987), Heizer et al. (2017); Piercy (2012) and Valhondo et al. (2014).

Evolution from Management Approaches

In line with the above, the different positions in operations management, related to their historical evolution, will be presented See Figure 4).

Note: the figure appears in its original language.

Source: Own elaboration.

Manufacturing management

Any production process is, first and foremost, an input-output system in which the management of the transformation process is understood from production. Therefore, production research involves a varied set of elements, both physical and chemical, which is supported by a technological base. As a result, production management, from its foundations, is an intuitive amalgam of observation, experience, and judgment.

In 1964, Starr states that production management has been associated almost exclusively with manufacturing operations throughout the first 60 years of the twentieth century; not surprisingly, the Queuing Theory approach, in its first version proposed by Erlang in 1909, focused primarily on the times that different types of agents had along a sequence of processes. For this reason, the problems of production scheduling and maintenance of optimal inventories, among others, were the main concerns at that time (Valhondo et al., 2014). A rational understanding of the economic and technological problems related to applying the principle of interchangeability, which Whitney developed in 1790, was one of the triggers on which a process orientation instead of product orientation was based (Valhondo et al., 2014).

The findings mentioned in Table 1 from the eighteenth century to the first half of the twentieth century, stand out as being closely related to the development of analytical procedures that fragment and divide manufacturing operations into smaller and smaller units to be studied in depth, i.e., a systematic approach to the manufacturing process with bottom-up management, in which microeconomics predominates and, therefore, formal modeling to social situations, in which several players try to maximize their profits, typical of Von Neumann's game theory, which is more convenient for companies (Leonard, 1995).

High production volumes, which began to establish themselves hand in hand with high competitiveness in the 1960s, constituted the first challenges in management that demanded a shift from a bottom-up approach to a top-down approach, as proposed by Skinner (1969). At the same time, treating the inventory problem separately from the production scheduling problem without considering machine replacement, plant design, and location is reasonable. In the case of highly interdependent subsystems, they must be linked together to resolve the management problem adequately.

The level of complexity of those situations with higher degrees of interdependence leads to the use of simulation, as in Jay Forrester's work on system dynamics. Hand in hand with the cybernetic approach to system dynamics, the analysis of the efficiency of organizations from a structural approach leads to the adoption of the Contingency Theory of Burns and Stalker (Zapata et al., 2009), Lawrence and Lorsch (1967), Woodward (1981). This serves as a sociological conceptual framework for analyzing flexible manufacturing. Thus, the nature of the economic analysis, which will later allow studying the consequences of outsourcing, is supported by Williamson's (1987) Transaction Theory.

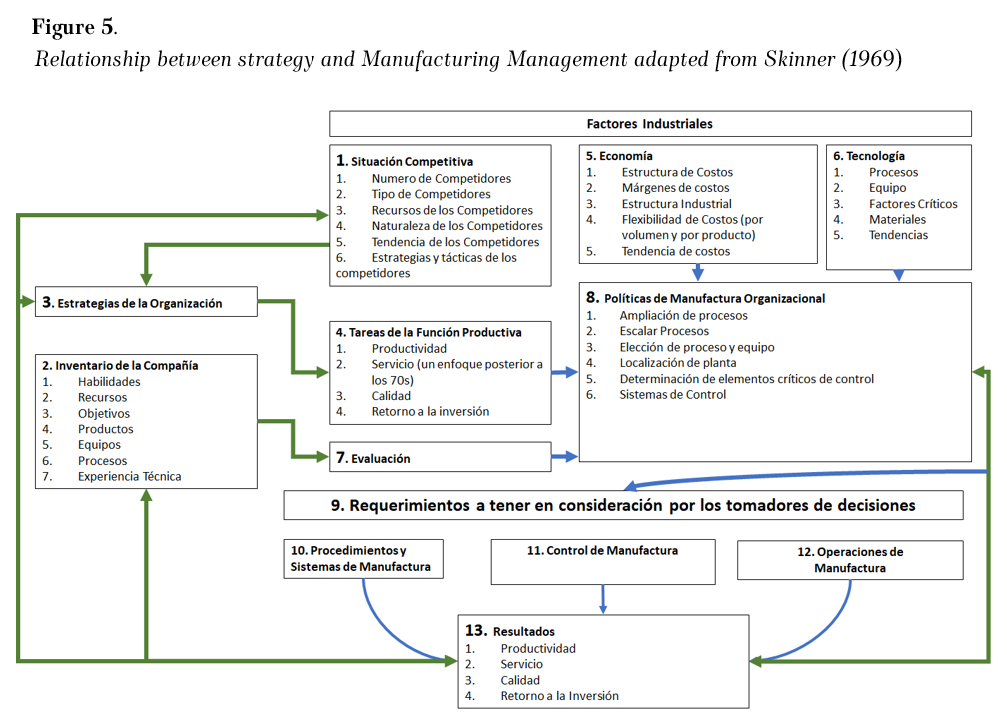

Operations management

Increasing competitiveness results from high production volumes, which makes it necessary to rethink manufacturing management. In his work, Skinner (1969) establishes a scheme more focused on strategy (see figure 5), which undoubtedly serves as a justification for the Porterian approach centered on competitive improvement in the market about the industrial forces of its operating environment based on the Industrial Theory of Organizations (Porter, 1980).

Note: the figure appears in its original language. The lines in green correspond to the evolution from the button-up to the top-down approach.

Source: Own elaboration.

Porter's structural view promotes more holistic characteristics in which resources and constraints demarcate a roadmap for appropriate processes and operations. Theoretical approaches such as the Resource-Based Vision Theory proposed by Barney (2001) and Goldratt's Theory of Constraints (Gupta & Boyd, 2008) succeed in establishing a framework for managing the system's performance and its portfolio of core competencies holistically.

The shift from manufacturing to operations management would certainly only have been managed with the help of the information boom of the 1980s, which, although stemming from the previous decade, only emerged almost ten years later. Goldratt's and Barney's approaches call for the flow of information, which would only have been consolidated with the information boom. The best evidence for this claim is found in the work of Jensen and Meckling in 1976 with the Agency Theory, which analyzes the consequences and managerial implications of several forms of information asymmetry (Eisenhardt, 1989).

Thanks to the new prominence of information management, operations restructured their short-run vision towards an integrated short-run vision, in which supply chain, operations strategies, new product development, and total quality are more frequently used in the same context. Through this, Pfeffer and Salancik's resource dependency theory (Pfeffer & Salancik, 2003) and DiMaggio and Powell's Institutional Theory (Suddaby, 2010) appear as new managerial bases to cope with the demands of external actors or organizations, whose resources are highly dependent on organizations, social processes and structures that influence social behavior per se.

Operations and supply management

Proponents of business process reengineering (BPR) have proposed that business structures based on traditional functional areas - sales, finance, and production, among others - should be more detailed under the realities of the 1990s and suggest that companies should be organized according to the processes employed. These processes have to do mainly with how things are done rather than with what is done (Craig & Yetton, 1993). For BPR, four objectives are established: 1) identify the process to be redesigned; 2) model the processes; 3) measure using diagnostic equipment; and 4) improve the process using a project approach (Williams et al., 2003). With the introduction of Checkland's systems approach (Checkland, 1995), all phenomena can be viewed as a network of relationships between elements, that is, as a system with common patterns, behaviors, and properties. As a result, measures such as market value added (MVA) and economic value added (EVA) acquired a relevant role in the decisions involved in allocating resources according to the product line.

The questioning of performance measures for the internal workings of organizations and traditional cost accounting (Kaplan & Norton, 1996) took up and re-evaluated the approach already introduced by Henry L. Gantt and Frank B. Gilbreth in 1919. In the face of the fact that man possesses only limited rationality, the complexity of manufacturing systems makes it virtually impossible to understand a system in its entirety. The reductionist approach considers that all phenomena can be decomposed into subsystems, whereas the holistic perspective states that systems can only be understood as indivisible wholes. In either case, it is impossible to experiment with real live systems to understand their behavior or attempt to improve; therefore, it is necessary to develop models that take a process view and incorporate a variety of business performance measures. Under this approach, works such as Granovetter (1992) and Wu et al. (2013), with their Network Theory, take on important significance in the dynamic analysis of processes in organizations. Additionally, hand in hand with relationships, the behavioral theory approach of Payne et al. (1993) allows to address aspects of Operations Management at the individual level. This framework and its core theories expanded the tools to understand, for example, consumer behavior, negotiation techniques, and management decision-making in order to improve the definition of relationships and their information flows.

Integrated operations management

Undoubtedly, the integral vision in operations has its main source of inspiration in sustainability. The entry on the scene of the social exchange theory by Autry and Whipple (2013) and Schaltegger and Burritt (2014) observes the relationships posed by each interrelationship between the areas of the organization, along with the relationships existing between each link in the supply chain. This sociological approach to processes in the role of the production manager is complemented by the arrival of the control theory of both Chan and Walker (Walker, 2014), with whom the control of dynamic systems is analyzed as a study of the inputs of a system to have the desired effect on the outputs. Although strongly marked by the vision of efficiency and effectiveness coming from manufacturing management, this approach provides the production and operations sector with a long-term vision, progressively controlled by the Deming current of continuous improvement.

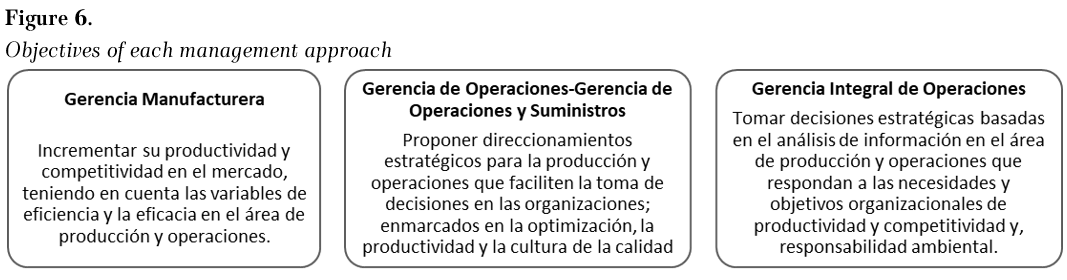

DISCUSIÓN

Under this framework and seeking to strengthen all those competencies that allow attaining a professional capable of facing the challenges mentioned here, business administration programs should articulate these elements throughout three cycles. Figure 6 shows the competencies by cycle.

Note: the figure appears in its original language.

Source: Own elaboration.

The above is aligned with what Cardona et al. (2017) affirm, for whom administrative practice is a fundamental element that drives the economic development of the region and the country since companies, through management systems, participate in the rational use of resources. From this perspective, it is not only a matter of producing more or less but also of establishing guidelines that consolidate the productive process and the organizational dynamics, the responsibility, care, and commitment of the organizations with the individual, the communities, and the environment. In this way, Pietro and Hamra (2021) express that it is possible to redesign processes, products, and services thanks to conscious business management. For organizations, this becomes a fundamental component of the dynamics of a globalized economy by market trends and technological advances.

Challenges associated with the technological environment and the business model

In the era of digital transformation, companies are seeking new opportunities to reshape their business structure and transform their operations, to achieve greater customer interaction and collaboration, and to gain competitive advantage through differentiation strategies (Ahuja & Chan, 2014; Rodriguez, 2017; Russell et al., 2018). Recent studies show how companies with a coherent plan to integrate both digital and physical operations components can successfully transform their business models, optimize all elements of the value chain, and meet the needs of their stakeholders (Bednall et al., 2018; Rönkkö & Herneoja, 2021). Companies that seek to generate new value propositions for stakeholders by transforming their operating models must also develop new capabilities. Companies must constantly explore new ways to capture revenue, structure business activities, and position themselves in new or existing industries. This requires interaction with stakeholders at all stages of business activity, not only through sales, marketing, and service but also through product or service design (Tae et al., 2020), supply chain management (Büyüközkan & Göçer, 2018), human resources (Bogoviz et al., 2019) and information technology (Bresnen, 2017).

Due to climate change, acting sustainably has become a requirement for organizations. Within this scenario, Industry 4.0 is a trendy initiative in industry that aims to innovate production processes towards sustainable practices by using advanced digital technologies on the assembly line (Nicoletti, 2020).

Challenges associated with production factors

The digital ecosystem integrates people, processes, business, and data to enable organizations to drive transformation and improve business outcomes. It should be noted that when digital transformation occurs, organizations with limited resources and competencies extend beyond the boundaries of their industry to seek new ways to support their business through cooperative and interactive relationships with partners. In this sense, organizations and business processes must be integrated through a digital ecosystem strategy and adopt new systems and tools to deliver value to stakeholders through increased data flow and knowledge sharing.

Advances in digital transformation - artificial intelligence (Chalmers et al., 2021), cloud computing, and the Internet of Things. Blockchain, big data, smart work (Colbert et al., 2018), and interoperability of information systems, among others - are changing the nature of the link between technology and employment. These changes will also bring benefits since, beyond labor substitution, production levels increase, quality is improved, and automation reduces errors. Therefore, the increasing use of automation and other digital technologies in organizations implies that information systems will gradually replace traditional workers in performing routine and codifiable tasks and increase workers' productivity by providing problem-solving skills. On the other hand, new co-production schemes are encouraged - participatory production - leading to empowerment and market development. In the case of participatory co-production, this means quality improvements in both public and private services (Osborne et al., 2016).

CONCLUSIONS

This research has made it possible to establish the marked role that technology has played in the evolution of production and operations management. It is observed how the hegemonic short-term vision during the 20th century still determines many guidelines of what some would consider the adequate managerial vision; however, the challenges above and the digital dynamics demand a long-term vision in which the analysis of customer needs, the knowledge acquired by the organization and competitiveness are combined.

It is therefore recommended to conduct empirical studies that evaluate a long-term vision in which companies have advantages when they migrate from approaches focused on short-term competitive advantages - use of resources centered on the production process - to long-term ones in which knowledge management supports the entire production process

.

REFERENCES

Aguilar-Barceló, J. e Higuera-Cota, F. (2019). Los retos en la gestión de la innovación para América Latina y el Caribe: Un análisis de eficiencia. https://acortar.link/wLdKaA

Ahuja, S., y Chan, Y. (2014). The Enabling Role of IT in Frugal Innovation Completed Research Paper. https://acortar.link/xaB4yz

Autry, C., y Whipple, J. (2013). Special issue on sustainability and resource scarcity. International Journal of Physical Distribution & Logistics Management, 43(5/6). https://doi.org/10.1108/ijpdlm.2013.00543eaa.001

Barber, K., Dewhurst, F., Burns, R. y Rogers, J. (2003). Business‐process modelling and simulation for manufacturing management: A practical way forward. Business Process Management Journal, 9(4), 527–542. https://doi.org/10.1108/14637150310484544

Barney, J. (2001). Resource-based theories of competitive advantage: A ten-year retrospective on the resource-based view. Journal of Management, 27(6), 643–650. https://doi.org/10.1177/014920630102700602

Barrientos, P. (2017). Marketing internet = e-commerce: Oportunidades y desafíos. Revista Finanzas y Política Económica, 9(1), 41-56. https://doi.org/10.14718/revfinanzpolitecon.2017.9.1.3

Bednall, T., Rafferty, A., Shipton, H., Sanders, K., y Jackson, C. (2018). Innovative Behaviour: How Much Transformational Leadership Do You Need? British Journal of Management, 29(4), 796–816. https://doi.org/10.1111/1467-8551.12275

Bessant, J. y Tidd, J. (2007). Innovation and entrepreneurship. John Wiley & Sons.

Bogoviz, A., Lobova, S. y Ragulina, J. (2019). The Cost and Value of Human Capital in the Modern Digital Economy. En E. G. Popkova (Ed.), The Future of the Global Financial System: Downfall or Harmony (pp. 1224–1230). Springer International Publishing.

Bresnen, M. (2017). Being careful what we wish for? Challenges and opportunities afforded through engagement with business and management research. Construction Management and Economics, 35(1–2), 24–34. https://doi.org/10.1080/01446193.2016.1270462

Buchanan, S. y Gibb, F. (2007). The information audit: Role and scope. International Journal of Information Management, 27(3), 159–172. https://doi.org/10.1016/j.ijinfomgt.2007.01.002

Buffa, E. y Sarin, R. (1987). Modern Production/Operations Management. John Willey & Sons. Inc., ABD, 190.

Büyüközkan, G. y Göçer, F. (2018). Digital Supply Chain: Literature review and a proposed framework for future research. Computers in Industry, 97, 157–177. https://doi.org/10.1016/j.compind.2018.02.010

Cárdenas, C., Molina, L., Cancino, G., Villalobos, S. de los S., Anaya, E., Díaz, I. y Ramírez, S. (2021). Utilización de microorganismos para una agricultura sostenible en México: Consideraciones y retos. Revista mexicana de ciencias agrícolas, 12(5), 899–913. https://doi.org/10.29312/remexca.v12i5.2905

Cardona, D., Rada, A., & Palma, H. (2017). Creación de empresa como pilar para el desarrollo social e integral de la región caribe en Colombia: Apuntes críticos. Saber, Ciencia y Libertad, 12(1), 134–143. https://doi.org/10.18041/2382-3240/saber.2017v12n1.698

Chalmers, D., MacKenzie, N. y Carter, S. (2021). Artificial Intelligence and Entrepreneurship: Implications for Venture Creation in the Fourth Industrial Revolution. Entrepreneurship Theory and Practice, 45(5), 1028–1053. https://doi.org/10.1177/1042258720934581

Chase, R. y Aquilano, N. (2008). Operations and Supply Management (10th edition). MacGraw Hill.

Checkland, P. (1995). Model validation in soft systems practice. Systems Research, 12(1), 47–54. https://doi.org/10.1002/sres.3850120108

Colbert, D., Tyndall, I., Roche, B., y Cassidy, S. (2018). Can SMART Training Really Increase Intelligence? A Replication Study. Journal of Behavioral Education, 27(4), 509–531. https://doi.org/10.1007/s10864-018-9302-2

Craig, J., y Yetton, P. (1993). Business Process Redesign: A Critique of Process Innovation by Thomas Davenport as a Case Study in the Literature. Australian Journal of Management, 17(2), 285–306. https://doi.org/10.1177/031289629301700207

Dalkir, K. (2011). Knowledge Management in Theory and Practice. Routledge. https://doi.org/10.4324/9780080547367

Eisenhardt, K. (1989). Agency Theory: An Assessment and Review. Academy of Management Review, 14(1), 57–74. https://doi.org/10.5465/amr.1989.4279003

Fujimoto, T. (1999). The Evolution of a Manufacturing System at Toyota. Oxford University Press.

Granovetter, M. (1992). Economic Institutions as Social Constructions: A Framework for Analysis. Acta Sociologica, 35(1), 3–11. https://doi.org/10.1177/000169939203500101

Gupta, M., y Boyd, L. (2008). Theory of constraints: A theory for operations management. International Journal of Operations & Production Management, 28(10), 991–1012. https://doi.org/10.1108/01443570810903122

Heizer, J., Render, B., y Munson, C. (2017). Operations management: Sustainability and supply chain management (12th edition). Pearson Education.

Hillmer, S., y Karney, D. (1997). Towards understanding the foundations of Deming’s theory of management. Journal of Quality Management, 2(2), 171–189. https://doi.org/10.1016/S1084-8568(97)90002-X

Kaplan, R. y Norton, D. (1996). Strategic learning & the balanced scorecard. Strategy & Leadership, 24(5), 18–24. https://doi.org/10.1108/eb054566

Larsen, M., Manning, S. y Pedersen, T. (2013). Uncovering the hidden costs of offshoring: The interplay of complexity, organizational design, and experience. Strategic Management Journal, 34(5), 533–552. https://doi.org/10.1002/smj.2023

Lawrence, P. y Lorsch, J. (1967). Differentiation and Integration in Complex Organizations. Administrative Science Quarterly, 12(1), 1–47. https://doi.org/10.2307/2391211

Leonard, R. (1995). From Parlor Games to Social Science: Von Neumann, Morgenstern, and the Creation of Game Theory 1928-1944. Journal of Economic Literature, 33(2), 730–761.

Lepadatu, D. y Janoski, T. (2020). Framing and Managing Lean Organizations in the New Economy. Routledge. https://doi.org/10.4324/9781351015158

Meredith, J. y Pilkington, A. (2018). Assessing the exchange of knowledge between operations management and other fields: Some challenges and opportunities. Journal of Operations Management, 60, 47–53. https://doi.org/10.1016/j.jom.2018.05.004

Nicoletti, B. (2020). Procurement 4.0 and the Fourth Industrial Revolution: The Opportunities and Challenges of a Digital World. Springer Nature.

Osborne, S., Radnor, Z. y Strokosch, K. (2016). Co-Production and the Co-Creation of Value in Public Services: A suitable case for treatment? Public Management Review, 18(5), 639–653. https://doi.org/10.1080/14719037.2015.1111927

Payne, J., Payne, J., Bettman, J. y Johnson, E. (1993). The Adaptive Decision Maker. Cambridge University Press.

Pfeffer, J. y Salancik, G.(2003). The External Control of Organizations: A Resource Dependence Perspective. Stanford University Press.

Piercy, N. (2012). Business history and operations management. Business History, 54(2), 154–178. https://doi.org/10.1080/00076791.2011.631121

Pietro, S. y Hamra, P. (2021). Diseñar hoy: Visión y gestión estratégica del diseño. Nobuko.

Porter, M. (1980). Industry Structure and Competitive Strategy: Keys to Profitability. Financial Analysts Journal, 36(4), 30–41. https://doi.org/10.2469/faj.v36.n4.30

Rodríguez, J. (2017). Transformaciones tecnológicas, su impacto en el mercado de trabajo y retos para las políticas del mercado de trabajo. https://repositorio.cepal.org/handle/11362/42612

Rönkkö, E. y Herneoja, A. (2021). Working across Boundaries in Urban Land Use and Services Planning—Building Public Sector Capabilities for Digitalisation. Smart Cities, 4(2), 767–782. https://doi.org/10.3390/smartcities4020039

Russell, K., O’Raghallaigh, P., O’Reilly, P. y Hayes, J. (2018 de septiembre). Business to digital transformation: A proposed framework for achieving business intelligence alignment. Irish Academy of Management Annual Conference 2018. https://cora.ucc.ie/handle/10468/7125

Schaltegger, S. y Burritt, R. (2014). Measuring and managing sustainability performance of supply chains: Review and sustainability supply chain management framework. Supply Chain Management: An International Journal, 19(3), 232–241. https://doi.org/10.1108/SCM-02-2014-0061

Shaw, I. (2021). Ancient Egypt: A Very Short Introduction. Oxford University Press.

Shingo, S. y Robinson, A. (Eds.). (2017). Modern Approaches to Manufacturing Improvement: The Shingo System. Routledge. https://doi.org/10.1201/9780203746745

Silva, A. y Gómez, D. (2018). Inclusión digital y los retos para la innovación educativa en Brasil y Colombia. Revista Iberoamericana de Psicología: Ciencia y Tecnología, 11(3), 81–88. https://doi.org/10.33881/2027-1786.rip.11307

Skinner, W. (1969, mayo 1). Manufacturing—Missing Link in Corporate Strategy. Harvard Business Review. https://hbr.org/1969/05/manufacturing-missing-link-in-corporate-strategy

Suddaby, R. (2010). Challenges for Institutional Theory. Journal of Management Inquiry, 19(1), 14–20. https://doi.org/10.1177/1056492609347564

Tae, C., Luo, X., y Lin, Z. (2020). Capacity-constrained entrepreneurs and their product portfolio size: The response to a platform design change on a Chinese sharing economy platform. Strategic Entrepreneurship Journal, 14(3), 302–328. https://doi.org/10.1002/sej.1360

Valderrama, R. y Tovar, L. (2008). La teoría de la complejidad: Una nueva disciplina multicientífica y sus bases para la aplicación en la administración. Revista Universidad y Empresa, 10(14), 129–154. https://acortar.link/wKsbNp

Valhondo, J., Sáez, F. y Banús, J. (2014). Organización de la producción: Una perspectiva histórica. Reial Acadèmia de Doctors. https://dialnet.unirioja.es/servlet/libro?codigo=761161

Walker, R. (2014). Internal and External Antecedents of Process Innovation: A review and extension. Public Management Review, 16(1), 21–44. https://doi.org/10.1080/14719037.2013.771698

Williams, A., Davidson, J., Waterworth, S. y Partington, R. (2003). Total quality management versus business process re-engineering: A question of degree. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 217(1), 1–10. https://doi.org/10.1177/095440540321700101

Williamson, O. (1987). Transaction cost economics: The comparative contracting perspective. Journal of Economic Behavior & Organization, 8(4), 617–625. https://doi.org/10.1016/0167-2681(87)90038-2

Woodward, J. (1981). Industrial Organization: Theory and Practice (Vol. 2). Oxford: Oxford University Press. https://doi.org/10.1177/017084068100200219

Wu, Y., Huatuco, L., Frizelle, G. y Smart, J. (2013). A method for analysing operational complexity in supply chains. Journal of the Operational Research Society, 64(5), 654–667. https://doi.org/10.1057/jors.2012.63

Zapata, G., Mirabal, A. y Hernández, A. (2009). Modelo teórico conceptual de la estructura organizativa: Un análisis contingente. Ciencia y Sociedad, 34(4), 618–640. https://doi.org/10.22206/cys.2009.v34i4.pp618-640

FINANCING

No external financing.

DECLARATION OF CONFLICT OF INTEREST

The author declares no conflict of interest.

ACKNOWLEDGMENTS

The author would like to thank Professor José Meyer Gómez for the valuable discussions held during the preparation of this document and the synthesis presented here.

AUTHORSHIP CONTRIBUTION

Conceptualization: Nicolás Afanador Cubillos.

Research: Nicolás Afanador Cubillos.

Methodology: Nicolás Afanador Cubillos.

Writing - original draft: Nicolás Afanador Cubillos.

Writing - revision and editing: Nicolás Afanador Cubillos.