doi: 10.58763/rc2023113

Scientific and Technological Research Article

Lean construction methodology in the optimization of the results of a building project

Metodología de construcción esbelta en la optimización de los resultados de un proyecto de edificación

Pedro Estrada Herrera1

![]() *, Jorge Pueblita Mares1

*, Jorge Pueblita Mares1 ![]() *

*

ABSTRACT

Within lean manufacturing applications, its contextualization in construction processes is found as lean construction. This approach aims to reduce non-value-adding activities by optimizing processes to maximize efficiency. Thus, the objective of this research was to propose a procedure for adopting the lean construction methodology to contribute to the optimization of building projects. A mixed-method study was conducted with a cross-sectional, descriptive focus based on the case study: construction of a recreational theme park for terminally ill children. A procedure structured in six steps was designed, allowing the adoption of the lean philosophy in project management and the design of a tool to assess the project team's competencies in integrated management systems. The results enabled the definition, design, and delivery of project assets with the highest possible value generation, where lean methodology principles were applied. Likewise, the integrated project systems, stemming from incorporating lean methodology principles, optimized project productivity in building construction.

Keywords: project management, construction engineering, lean manufacturing, development project.

JEL Classification: D24; O14.

RESUMEN

Palabras clave: dirección de proyecto, ingeniería de la construcción, manufactura esbelta, proyecto de desarrollo.

Clasificación JEL: D24; O14.

Received: 22-03-2023 Revised: 17-05-2023 Accepted: 15-06-2023 Published: 04-07-2023

Editor: Carlos Alberto Gómez Cano ![]()

1Universidad La Salle de Cuernavaca. Cuernavaca, México.

Cite as: Estrada, P. y Pueblita, J. (2023). Metodología de construcción esbelta en la optimización de los resultados de un proyecto de edificación. Región Científica, 2(2), 2023112. https://doi.org/10.58763/rc2023113

INTRODUCTION

The lean philosophy had its origin in the manufacturing applied in the Toyota production line, thus, its development was framed in the events that occurred during the World War II, which promoted its rapid adoption by the United States and its generalization in the industry. (Carrilo et al., 2019; Singh and Kumar, 2020; Dallasega et al., 2020; de Souza et al., 2023). In this way, it was recognized as a methodology focused on reducing waste classified as: waiting, defects, unnecessary movements, excess inventory, overproduction, saturated transportation and large-scale processing (Martínez et al., 2016; Kumar et al. , 2022).

In this context, its implementation has allowed the optimization of processes and the elimination of harmful practices (Amado et al., 2020; Francis & Thomas, 2020; Shaqour, 2022). Therefore, several researchers have translated the lean manufacturing (FLM) philosophy into spanish as lean manufacturing, lean manufacturing, and agile manufacturing (Sanchez, 2023). This process has been carried out through the following production systems: Total Quality Management (TQM), Just in Time (JIT), Kaizen (Continuous Improvement), Theory of Constraints (TOC), and Process Reengineering (Sirvent et al., 2016). In turn, it has been a practical methodology focused on increasing the efficiency of processes by implementing the Kaizen management philosophy of continuous improvement in time and space. It has been directed to discard waste (Guerrero et al., 2019).

Thus, applications have been evidenced in the production sector: lean production, lean manufacturing, lean supply chain, lean construction; also in services: lean government, lean hotel, lean accounting and in the health area under the name of lean Healthcare with a broad representation in the literature (Zambrano et al., 2022). In construction projects (CP), they have focused on reducing activities that do not generate value based on the quality of processes in order to maximize efficiency and minimize waste (Gao et al., 2023; Michalski et al., 2022; Yücenur & Şenol, 2021).

Thus, unlike other industries that have evolved thanks to technology, construction has been relatively static in its processes, making adopting new methods and tools necessary to increase productivity and efficiency (Barbhuiya & Bhusan, 2023). How various works are carried out obeys an artisanal and unproductive mode, which has persisted since ancient times without significant changes.

Thus, the lean construction methodology offers opportunities to optimize the phases as well as processes in projects (Caballero et al., 2018), which facilitates their management and allows reducing waste while maximizing the value of the project through the use of practical tools and techniques (Aureliano et al., 2019; Goh & Goh, 2019; Aslam et al., 2020; Abu et al., 2022). In this regard, there are significant differences between traditional project management (TPM) and the approach proposed by the lean philosophy, which are presented in table 1.

|

Table 1. Main differences between traditional project management and the lean approach |

|

|

GTP |

Lean Construction |

|

Completion of all project activities (those that may or may not add value are not demonstrated). |

Maximize value and minimize project overrun.

|

|

Master planning is carried out at the beginning of the project. Only what was planned from the beginning is executed. |

Replanning in correspondence to the executed results, which maintains the continuous work flow.

|

|

Lessons learned at project closure. |

The root cause of problems is identified at the exact moment they occur.

|

|

Certain elements are defined at the beginning of the project in a formal manner without generating transformations (frozen scope). |

The value of the project is defined and its life cycle is set in motion. |

|

A traditional work is programmed through the progress of a master plan. |

Tasks are coordinated before being executed in order to generate a continuous flow of work and "pull" techniques are used. |

|

Resources are allocated to accomplish tasks. |

It is collaborative with efficient use of the resources that are employed. |

|

Centralized decision making (usually top management). |

Decision making through the project team. |

|

Culture of individual achievement and compliance. |

Malleable and adaptive culture, success is the result of teamwork. |

Source: own elaboration.

Based on the potential of applying this new management approach, the objective of this study was to propose a procedure for adopting the lean construction methodology to contribute to the optimization of building projects.

METHODS

The study was implemented using a multi-method approach based on a mixed embedded design (Hernández & Mendoza, 2018). For this design, Harrison et al. (2020) recommendations on the rigor of mixed studies were considered. A descriptive cross-sectional research was used, based on the case study: design and construction of a recreational theme park for terminally ill children, an innovative and unprecedented project in Mexico.

A "fast track" construction management system was implemented (Ballesteros et al., 2019) to meet all client requirements. In this way, it allowed the planning of activities in parallel in order to decrease total project times and strategies used in classical project compression. In this way, activities, their precedence and completion times, and elements supporting the critical path's construction were identified (Méndez et al., 2023). In this sense, in planning, it is essential to have the complete project to obtain the corresponding license and the appropriate financial resources.

For the design and execution of the project, the traditional model was chosen, known as bidding-construction, which generally has as its implementation methodology the design-bidding-construction route (Wang & Chen, 2023). It should be noted that this methodology still needs to improve, among which are labor incidents, works being carried out within an unspecified period, cost overruns, requirements due to poor quality, and, in general, uncertainty concerning the conditions initially proposed in the contract. Therefore, a hybrid procedure was proposed that considered the "Fast Track" method and FLM contextualized as lean construction (Aureliano et al., 2019), thus minimizing the impact of chronic construction problems to ensure cost and quality.

The procedure was structured in six steps:

· Step 1. Identification of initial scope deficiencies: A set of original scope deficiencies was identified based on the monitoring of project activities.

· Step 2. Analysis of initial scope deficiencies: Based on the analysis of the initial scope deficiencies, it was possible to propose possible solutions for improvements that would make it possible to maintain the quality policies in the project's construction and, in turn, to maintain the service level set.

· Step 3. Identification of chronic construction problems: Problems related to project management were identified and described clearly and precisely for discussion with the project team and those financing the work.

· Step 4. Evaluation of experts' knowledge: An instrument was designed to evaluate the experts' competencies, which revealed the knowledge related to the management of building projects using integrated management systems and the methodology derived from the lean philosophy.

· Step 5. Lean analysis of the project information: A theoretical analysis of the impact of the lean methodology on the project information was carried out to identify possible improvements.

· Step 6. Strategy design: New strategies to be adopted by the project team to manage building works were defined. New management forms were integrated to raise the level of service and reduce waste.

A questionnaire was applied as an instrument to 25 professionals (architects, engineers, and technicians) who were part of the project team. Competencies related to design, service level, management systems, and willingness to change in the project management approach were also evaluated.

RESULTS

Application of the lean project management procedure.

The primary deficiencies related to the project's scope were identified and described after its implementation. Table 2 below shows everything related to the areas of the construction work, while table 3 shows the general infrastructure problems.

|

Table 2. Deficiencies related to the scope of the project (areas of construction work) |

|

|

Problem |

Description |

|

Aquatic park: undefined scope of the pool. |

As this was a parameterized budget, the scope of a wave pool and water toys were not defined. |

|

Castle: over-engineered metal structure. |

The structural design of the castle was not optimized, so a lighter design was required and an overdesign of 40% was estimated. |

|

Villas/Lodging: increase to double the initial units. |

Due to the need for more sponsors, the demand for villas doubled. |

|

Main entrance: themed metal structure. |

It was necessary to change the prefabricated construction system for one made on site. |

|

Table 3. Deficiencies related to the scope of the project (infrastructure) |

|

|

Problem |

Description |

|

Unpaved access road to the park and the right-of-way. |

3 km of dirt road that passes through the right-of-way during the rainy season is subject to erosion due to washout.

|

|

The hydraulic infrastructure lacks a deep well.

|

As the villas will be increased to double the capacity of the original reach, it will be necessary to increase the potable water supply.

|

|

Earthworks, lack of retaining walls and slope protection, |

The earthwork project does not consider retaining walls; areas will overlap due to the kicking of the walls. |

|

General theming of the park.

|

There is no theming project for all the areas of the park; a medieval aspect is required, which was not considered in the parametric cost. |

Source: own elaboration.

It is notorious that the specific items in the "initial scope" modify the balance of the triple constraint at the beginning of the project and affect the availability of resources. This reflects a project cost overrun of 40% of what was initially considered and a project duration estimated at 1.7 times more than the original schedule. In this sense, Kim et al. (2022) have performed a decommissioning risk analysis of a nuclear power plant planning project, where the main risks in initial states were evidenced: physical state, state and characterization of the conditions with problems, state of the materials and resources, and characteristics of the infrastructures.

In addition, the need to manage waste has been evidenced by contemplating policies, such as waste characterization and infrastructure and reuse of materials, where the circular economy stands out (Rondón et al., 2022). Once the missing and undefined aspects of the project were detected, an evaluation of the information available in the executive project was carried out to determine whether or not to continue with the execution of the project, as well as to decide whether to continue with the "Fast Track" method plan or to implement a different management methodology.

Thus, Bastante et al. (2019) have identified a set of advantages in the application of the Fast Track methodology, which has allowed overlapping activities (planning activities in parallel that increase the percentage of resource utilization), building at the same time as designing; increased times for design development; improvements in execution; and reduction of the total time of the work. From the analysis of the primary deficiencies detected at the beginning of the project, work meetings and brainstorming sessions were held among the project team to propose possible improvement solutions:

Improvement solutions for deficiencies in construction site areas

1. To carry out the executive project for the wave and aquatic games pool.

2. Increased cost and execution time.

3. Reengineer the value of the architectural project by redefining spaces to minimize the weight of the infrastructure.

4. Recalculate the foundations and load-bearing walls to build one more level.

5. Change the construction system to a permanent system with lower maintenance.

Improvement solutions for infrastructure deficiencies

1. To carry out improvement works in earthworks and later paving.

2. Request authorization for the drilling of a deep well.

3. To carry out geophysical studies.

4. To carry out the allocation of resources for the execution of a deep well.

5. Develop and cost a retaining wall project.

6. Modify the layout of the launching pads.

7. Increase the cost of earthwork items.

8. Develop a theming project for accesses, villas, warehouses, castles, and exterior areas.

9. Increase the cost of the project.

Consistent with the analysis, as detailed in table 4, a group of chronic problems related to critical elements for maintaining the level of customer service were identified.

|

Table 4. Chronic problems that compromise the level of service |

|

|

Problem |

Description |

|

Task Team. |

Lack of coordination and transparency among stakeholders. |

|

Cost. |

Cost overruns derived from the design-bid-build system. |

|

Defects of |

Production requiring rework. |

|

Safety. |

Poor safety compliance. |

|

Waste. |

Excessive resources misdirected by overproduction. |

Source: own elaboration.

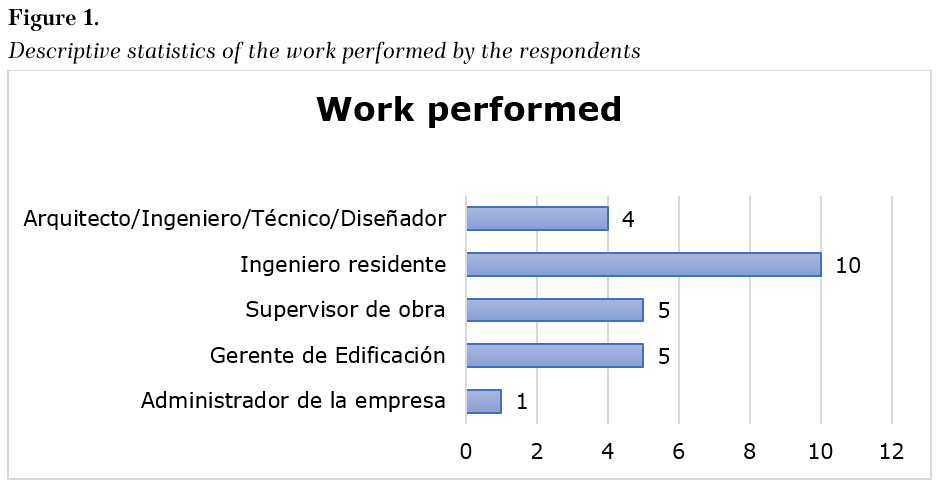

From the application of the survey to the project team, the results are summarized in table 5, which shows an analysis of the questions with dichotomous answers (questions 1, 5, 7, 8, 9, 10, 11, 12, 13, 14, 15 and 16), as follows: 100% of the respondents had participated in CPs, of which 10 (40%) had worked as resident engineers, 5 (20%) as construction supervisors, 5 (20%) as building managers, 4 (16%) as architects, engineers, technicians or designers and 1 (4%) as company administrator of the CPs, elements that are described in figure 1.

The professional experience in this type of project was 40% from one to five years, 24% from 10 to 15 years, 20% from five to 10 years, and 16% with more than 15 years (see Figure 2). On the other hand, 84% of the respondents evidenced that the information provided by the clients needed to be more sufficient for the adequate development of the project and for the fulfillment of the level of service expressed in terms of compliance with the budget and the fixed delivery time. 88% indicated they knew integrated management systems, BIM, lean manufacturing, PMBOK, and their advantages in project management. In turn, 76% stated that their institutions had tools that ensured compliance with delivery deadlines.

On the other hand, 76% stated that their institutions had macro indicator systems to manage project quality. However, 80% stated that the projects they participated in did not have technologies for continuous monitoring of quality-related risks. The same percentage stated they needed documents to ensure feedback and consolidation of good practices. They also considered it essential:

· 80% will have technologies for PC quality control to ensure project activities' planning.

· 96% of the strategic alignment between international project management standards and the implementation of policies for PC quality control.

· 100% would feel comfortable working in companies that have policies for project quality control and that have policies for PC quality control, allowing the definition, validation, and control of the productivity of the construction processes.

|

Table 5. Analysis of the dichotomous response questions in the survey |

|||||

|

Ask

|

Alternative |

Ask

|

Alternative |

||

|

Yes |

No |

Yes |

No |

||

|

1 |

25 (100%) |

- |

11 |

5 (20%) |

20 (80%) |

|

5 |

22 (88%) |

3 (12%) |

12 |

20 (80%) |

5 (20%) |

|

7 |

4 (16%) |

21 (84%) |

13 |

24 (96%) |

1 (4%) |

|

8 |

19 (76%) |

6 (24%) |

14 |

25 (100%) |

- |

|

9 |

19 (76%) |

6 (24%) |

15 |

24 (96%) |

1 (4%) |

|

10 |

5 (20%) |

20 (80%) |

16 |

25 (100%) |

- |

Source: own elaboration.

Source: own elaboration.

Note: the figure appears in its original language

Source: own elaboration.

Note: the figure appears in its original language

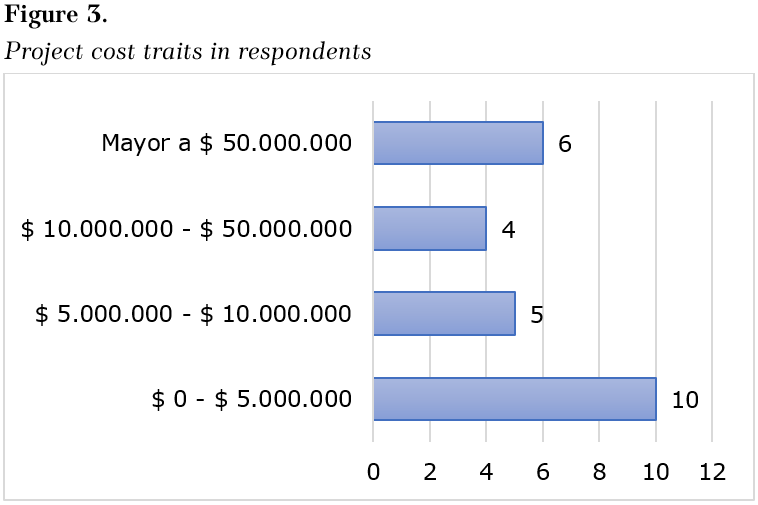

From the analysis of the costs of the projects in which the respondents had participated, it was found that 40% had participated in projects with costs of $ 0 - $ 5,000,000, 24% in costs greater than $ 50,000,000, 20% between $ 5,000,000 - $ 10,000,000 and 16% between $ 10,000,000 - $ 50,000,000, as described in Figure 3. 000,000 and 16% between $ 10,000,000 - $ 50,000,000, as shown in figure 3. Correspondingly, it was observed that the most significant participation was in public projects (20, which represented 80%) and the remaining 20% in private sector projects.

Source: own elaboration.

Note: the figure appears in its original language

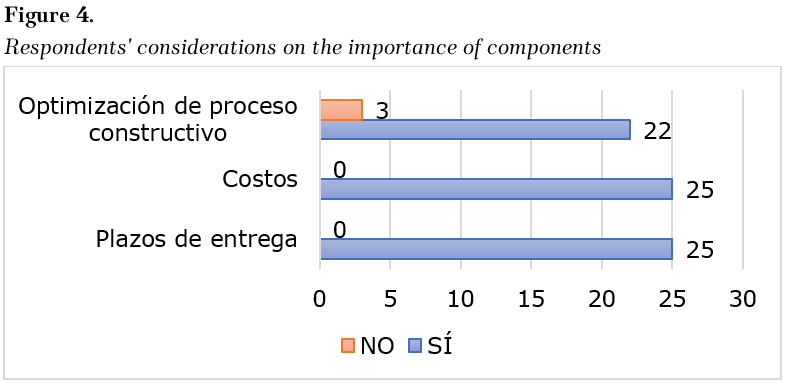

All (100%) respondents considered cost and delivery time components essential among the quality policies to maintain the established service level and productivity in the PCs. On the other hand, 22 (88%) considered project optimization or compression to be necessary. See figure 4.

Source: own elaboration.

Note: the figure appears in its original language

Thus, adopting the Lean Construction philosophy requires a paradigm transformation in how projects are carried out and designing new methods to implement all processes. It is about having the ability to provoke a transformational movement in current operations and redirect the mission and vision of the organization toward the total satisfaction of the internal and external customers. This implies continuously identifying the value stream to deliver the deliverables with effective and efficient parameters with the content, quality, time, and costs required in the project.

To support this new approach, the Integrated Project Delivery System (IPDS) was chosen (Mesa et al., 2016; Mesa et al., 2019), which allowed for defining, designing, supplying, constructing, and using the project assets, generating greater values. Thus, the IPDS has within it all the entities that are part of a project, shares both risks and utilities and incorporates related procedures among all collaborators in a given context that allows a broad collaborative work, thus reducing waste and promoting value generation (Kahvandi et al., 2020).

Determined the redirection of the management methodology for the theme park project, the following tools were chosen: Lean Construction (Michalski et al., 2022); Set-Based Design (Fitzgerald & Ross, 2019), which will be used to analyze the best solution for the project; Target et al. (Johansen et al., 2021), which is used to design the project based on Value Engineering or constructability properly; and Pull-type activity planning, which is used to confirm the value-generating activities in the project and as a prelude to the design of the production flow on-site.

In addition, the IPDS employs the Last Planner System for detailing site activities and constraint management (Montalbán et al., 2023) and Takt Planning for site workload balancing (Jabbari et al., 2020). All these Lean tools help to optimize workflow, reduce waste, and improve efficiency in PC execution.

In the case studied, it was observed that, despite being a team of people with experience and management of large projects, they did not have full knowledge of the new management methodologies, so with this implementation, the professionals were trained for the proper management of the variables of scope, time and cost, resulting in the construction of the project with minimal deviations. At the same time, it was possible to satisfy all the client's needs and requests to open the facilities with the best use of the invested resources.

In this sense, conducting analyses that address the importance of customer perception of the products they observe during the execution of the project is considered an essential element (Sánchez et al., 2022), as this will allow redesigning policies and aligning them more and more with what the customer demands.

CONCLUSIONS

Currently, integrated project systems, based on the superimposition of lean methodology precepts, optimize the productivity of building CPs. In this way, the methodology implementation balances the increase of the project's original scope in costs congruent to these updates, deadlines, and program, carried out in its maximum compression. This is why the park can be put into operation with a deviation in the initial investment of approximately a 5% increase, where minimal risks are achieved in the project through the lean methodology.

In this context, the project team is made up of specialists with experience in projects between one and five years, with more excellent representation in public sector projects, valued in the cost range of $ 0 - $ 5,000,000, most of whom recognize the need for integrated management in the programming of building projects. However, they show that the companies in which they have worked need more tools, methodologies, and procedures to integrate management systems to optimize project productivity, delivery costs, and delivery times to raise the level of service.

Finally, future studies should focus on the study of methodologies such as the circular economy, which makes it possible to optimize the use of resources by planning the reuse of waste, as well as to define indicators that make it possible to measure and control the project through monitoring parameters, all in order to act proactively in the event of the negative behavior of critical variables.

REFERENCES

Abu, Y., Tayeh, B., Alaloul, W. y Almalki, A. (2022). Health and safety improvement in construction projects: a lean construction approach. International Journal of Occupational Safety and Ergonomics, 28(4), 1981-1993. https://doi.org/10.1080/10803548.2021.1942648

Amado, K., Osorio, M., Molina, E. y Duarte, E. (2020). Desarrollo de la metodología lean healthcare en el servicio de medicina interna de la institución hospitalaria de carácter público. Revista Ingeniería, Matemáticas y Ciencias de la Información, 7(13), 45-56. https://doi.org/10.21017/rimci.2020.v7.n13.a74

Aslam, M., Gao, Z. y Smith, G. (2020). Exploring factors for implementing lean construction for rapid initial successes in construction. Journal of Cleaner Production, 277, 123295. https://doi.org/10.1016/j.jclepro.2020.123295

Aureliano, F., Costa, A., Júnior, I. y Rodrigues, R. (2019). Application of lean manufacturing in construction management. Procedia Manufacturing, 38, 241-247. https://doi.org/https://doi.org/10.1016/j.promfg.2020.01.032

Ballesteros, P., Elamrousy, K. y González, M. (2019). Non-linear time-cost trade-off models of activity crashing: Application to construction scheduling and project compression with fast-tracking. Automation in Construction, 97, 229-240. https://doi.org/https://doi.org/10.1016/j.autcon.2018.11.001

Barbhuiya, S. y Bhusan, B. (2023). Life Cycle Assessment of Construction Materials: Methodologies, Applications and Future Directions for Sustainable Decision-making. Case Studies in Construction Materials, 19, e02326. https://doi.org/https://doi.org/10.1016/j.cscm.2023.e02326

Bastante, M., Nina, F., González, M. y Miranda, J. (2019). Optimización de tiempos en obras civiles, aplicando el método Fast-Tracking. Estudio de caso. 23rd International Congress on Project Management and Engineering, Málaga, España. http://dspace.aeipro.com/xmlui/bitstream/handle/123456789/2271/AT02-014_2019.pdf?sequence=1

Caballero, S., Zambrano, B. y Ponce, E. (2018). Estado actual de la aplicación de la metodología lean construction en la gestión de proyectos de construcción en Colombia. Ingeniare (25), 39-65. https://dialnet.unirioja.es/servlet/articulo?codigo=7528666

Carrilo, M., Alvis, C., Mendoza, Y. y Cohen, H. (2019). Lean 5S y TPM, herramientas de mejora de la calidad. Caso empresa metalmecánica en Cartagena, Colombia. SIGNOS-Investigación en Sistemas de Gestión, 11(1), 71-86. https://doi.org/10.15332/s2145-1389-4934

Dallasega, P., Revolti, A., Sauer, P., Schulze, F. y Rauch, E. (2020). BIM, Augmented and Virtual Reality empowering Lean Construction Management: a project simulation game. Procedia Manufacturing, 45, 49-54. https://doi.org/10.1016/j.promfg.2020.04.059

de Souza, E., Rébula, U., de Carvalho, M., Aprigliano, V. y Teodoro, P. (2023). Sustainability in Public Universities through lean evaluation and future improvement for administrative processes. Journal of Cleaner Production, 382, 135318. https://doi.org/https://doi.org/10.1016/j.jclepro.2022.135318

Fitzgerald, M. y Ross, A. (2019). Artificial intelligence analytics with Multi-Attribute Tradespace Exploration and Set-Based Design. Procedia Computer Science, 153, 27-36. https://doi.org/https://doi.org/10.1016/j.procs.2019.05.052

Francis, A. y Thomas, A. (2020). Exploring the relationship between lean construction and environmental sustainability: A review of existing literature to decipher broader dimensions. Journal of Cleaner Production, 252, 119913. https://doi.org/10.1016/j.jclepro.2019.119913

Gao, M., Wu, X., Wang, Y. y Yin, Y. (2023). Study on the mechanism of a lean construction safety planning and control system: An empirical analysis in China. Ain Shams Engineering Journal, 14(2), 101856. https://doi.org/https://doi.org/10.1016/j.asej.2022.101856

Goh, M. y Goh, Y. (2019). Lean production theory-based simulation of modular construction processes. Automation in Construction, 101, 227-244. https://doi.org/10.1016/j.autcon.2018.12.017

Guerrero, D., Silva, J. y Bocanegra, C. (2019). Revisión de la implementación de lean six sigma en instituciones de educación superior. Ingeniare. Revista Chilena de Ingeniería, 27(4), 652-667. https://doi.org/10.4067/S0718-33052019000400652

Harrison, R., Reilly, T. y Creswell, J. (2020). Methodological Rigor in Mixed Methods: An Application in Management Studies. Journal of Mixed Methods Research, 14(4), 1-23. https://doi.org/10.1177/1558689819900585

Hernández, R., & Mendoza, C. (2020). Metodología de la investigación: las rutas cuantitativa, cualitativa y mixta. Mcgraw-hill. https://acortar.link/s6GbCk

Jabbari, A., Tommelein, I. y Kaminsky, P. (2020). Workload leveling based on work space zoning for takt planning. Automation in Construction, 118, 103223. https://doi.org/https://doi.org/10.1016/j.autcon.2020.103223

Johansen, A., Engbo, A., Torp, O. y Kalsaas, B. (2021). Development of target cost – By the owner or together with Contractors - Target Value Design. Procedia Computer Science, 181, 1171-1178. https://doi.org/https://doi.org/10.1016/j.procs.2021.01.314

Kahvandi, Z., Saghatforoush, E., ZareRavasan, A. y Viana, M. (2020). A review and classification of integrated project delivery implementation enablers. Journal of Construction in Developing Countries, 25(2), 219-236. https://doi.org/10.21315/jcdc2020.25.2.9

Kim, G., Kim, H., Seo, H., Yu, J. y Son, J. (2022). Classification and consideration for the risk management in the planning phase of NPP decommissioning project. Nuclear Engineering and Technology, 54(12), 4809-4818. https://doi.org/https://doi.org/10.1016/j.net.2022.07.022

Kumar, N., Shahzeb, S., Srivastava, K., Akhtar, R., Kumar, R. y Choubey, V. (2022). Lean manufacturing techniques and its implementation: A review. Materials Today: Proceedings, 64, 1188-1192. https://doi.org/https://doi.org/10.1016/j.matpr.2022.03.481

Martínez, P., Martínez, J., Nuño, P. y Cavazos, J. (2016). Mejora en el tiempo de atención al paciente en una unidad de urgencias gineco-obstétricas mediante la aplicación de Lean Manufacturing. Revista Lasallista de Investigación, 13(2), 46-56. https://doi.org/10.22507/rli.v13n2a5

Méndez, N., Oteiza, T., Suárez, A. y Sánchez, Y. (2023). Optimización temporal del proyecto de construcción de un parque infantil. Ciencias Holguín, 29(2), 1-11. https://www.redalyc.org/journal/1815/181574886007/181574886007.pdf

Mesa, H., Molenaar, K. y Alarcón, L. (2016). Exploring performance of the integrated project delivery process on complex building projects. International Journal of Project Management, 34(7), 1089-1101. https://doi.org/10.1016/j.ijproman.2016.05.007

Mesa, H., Molenaar, K. y Alarcón, L. (2019). Comparative analysis between integrated project delivery and lean project delivery. International Journal of Project Management, 37(3), 395-409. https://doi.org/10.1016/j.ijproman.2019.01.012

Michalski, A., Głodziński, E. y Bӧde, K. (2022). Lean construction management techniques and BIM technology – systematic literature review. Procedia Computer Science, 196, 1036-1043. https://doi.org/https://doi.org/10.1016/j.procs.2021.12.107

Montalbán, L., Casas, J., Alarcón, L. y Pellicer, E. (2023). Influence of the experience of the project manager and the foreman on project management’s success in the context of LPS implementation. Ain Shams Engineering Journal, 102324. https://doi.org/https://doi.org/10.1016/j.asej.2023.102324

Rondón, E., Lobo, A. y Gallardo, A. (2022). Circularity indicator for municipal solid waste treatment plants. Journal of Cleaner Production, 380, 134807. https://doi.org/https://doi.org/10.1016/j.jclepro.2022.134807

Sánchez, Y. (2023). Instrumento metodológico para la gestión de flujos de pacientes en instituciones hospitalarias [Tesis de doctorado, Universidad de Matanzas]. Repositorio UMCC. https://goo.su/aXJiucl

Sánchez, Y., Suárez, R., Quesada, A., Marqués, M., Leyva, S. y Santos, O. (2022). Estudio de la Infraestructura peatonal del centro histórico de la ciudad de Matanzas. Ingeniería Industrial, 43(1), 105-118. http://scielo.sld.cu/pdf/rii/v43n1/1815-5936-rii-43-01-105.pdf

Shaqour, E. (2022). The impact of adopting lean construction in Egypt: Level of knowledge, application, and benefits. Ain Shams Engineering Journal, 13(2), 101551. https://doi.org/10.1016/j.asej.2021.07.005

Singh, S. y Kumar, K. (2020). Review of literature of lean construction and lean tools using systematic literature review technique (2008–2018). Ain Shams Engineering Journal, 11(2), 465-471. https://doi.org/10.1016/j.asej.2019.08.012

Sirvent, J., Gil, M., Álvarez, T., Martin, S., Vila, N., Colomer, M., March, E., Loma-Osorio, P. y Metje, T. (2016). Técnicas «Lean» para la mejora del flujo de los pacientes críticos de una región sanitaria con epicentro en el servicio de medicina intensiva de un hospital de referencia. Medicina Intensiva, 40(5), 266-272. https://doi.org/10.1016/j.medin.2015.08.005

Wang, T. y Chen, H. (2023). Integration of building information modeling and project management in construction project life cycle. Automation in Construction, 150, 104832. https://doi.org/https://doi.org/10.1016/j.autcon.2023.104832

Yücenur, G. y Şenol, K. (2021). Sequential SWARA and fuzzy VIKOR methods in elimination of waste and creation of lean construction processes. Journal of Building Engineering, 44, 103196. https://doi.org/https://doi.org/10.1016/j.jobe.2021.103196

Zambrano, C., Lao, Y. y Moreno, M. (2022). Modelo de gestión del cambio organizacional con pensamiento lean en servicios turísticos. Contaduría y Administración, 67(1), 16-39. http://dx.doi.org/10.22201/fca.24488410e.2022.2912

FINANCING

No external financing.

DECLARATION OF CONFLICT OF INTEREST

None.

ACKNOWLEDGMENTS (ORIGINAL VERSION SPANISH)

Se agradece a la Universidad La Salle de Cuernavaca por el apoyo recibido para el desarrollo de la investigación.

AUTHORSHIP CONTRIBUTION

Conceptualization: Pedro Estrada Herrera and Jorge Pueblita Mares.

Research: Pedro Estrada Herrera and Jorge Pueblita Mares.

Methodology: Pedro Estrada Herrera and Jorge Pueblita Mares.

Writing - original draft: Pedro Estrada Herrera and Jorge Pueblita Mares.

Writing - revision and editing: Pedro Estrada Herrera and Jorge Pueblita Mares.